|

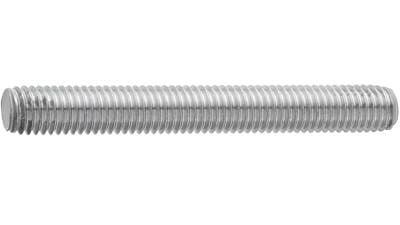

SDMA808

In Stock

|

|

|

SDMA810

In Stock

|

|

|

SDMA816

In Stock

|

|

|

SDMA820

In Stock

|

|

Stainless steel 1.4529 is known for its exceptional performance in demanding environments, making it a reliable choice for building and industrial applications.

At Anzor, we supply some of the world’s most advanced stainless steels. These grades are engineered for superior strength, corrosion resistance, and long-term performance in the toughest environments — from marine to coastal construction and aerospace applications. When a Stainless Steel Grade has a Pitting Resistance Equivalent Number (PREN) over 40, it is a 'SUPER' grade and should be fully resistant to localised corrosion (pitting/crevice corrosion) when immersed in seawater. These grades are not only 'SUPER' in terms of corrosion resistance, but many Anzor stock are also 'SUPER' in terms of strength and ductility (see Bumax DX129).

Indoor Swimming Pools are very different from outdoor swimming pools, and even seawater – they are one of the most corrosive environments to be found. It is not being in contact with the pool water that is an issue, but rather the atmosphere above it. Raised temperature, high humidity and chemicals in an aerosol form – especially Chlorine compounds.

In this environment, grades of stainless steel like 304, 316 and even 2205 can suffer Stress Corrosion Cracking (which is hard to detect), especially when these components are under load.

A fatal pool roof collapse in the early 1990s in Europe was due to stress corrosion cracking of 304 roof supports. Then after testing, the report suggested that 6% Mo alloys would NOT crack and subsequently the EU standard EN 13451 was created, which calls for stainless steel grades such as 1.4529 being used above indoor swimming pools for load bearing, safety critical components which are not regularly cleaned and exposed to indoor swimming pool environment.

Areas of application for 1.4529

Material 1.4529, also known as Alloy 926, is an austenitic special steel with a higher corrosion resistance than conventional chrome-nickel steel. Alloy 926 represents an enhancement to Alloy 904L (1.4539) stainless steel, with a raised molybdenum content and additional nitrogen. For this reason, the material is classified in the highest corrosion resistance class, CRC V.

|

SDMA808

In Stock

|

|

|

SDMA810

In Stock

|

|

|

SDMA816

In Stock

|

|

|

SDMA820

In Stock

|

|

Stainless steel 1.4529 is known for its exceptional performance in demanding environments, making it a reliable choice for building and industrial applications.

At Anzor, we supply some of the world’s most advanced stainless steels. These grades are engineered for superior strength, corrosion resistance, and long-term performance in the toughest environments — from marine to coastal construction and aerospace applications. When a Stainless Steel Grade has a Pitting Resistance Equivalent Number (PREN) over 40, it is a 'SUPER' grade and should be fully resistant to localised corrosion (pitting/crevice corrosion) when immersed in seawater. These grades are not only 'SUPER' in terms of corrosion resistance, but many Anzor stock are also 'SUPER' in terms of strength and ductility (see Bumax DX129).

Indoor Swimming Pools are very different from outdoor swimming pools, and even seawater – they are one of the most corrosive environments to be found. It is not being in contact with the pool water that is an issue, but rather the atmosphere above it. Raised temperature, high humidity and chemicals in an aerosol form – especially Chlorine compounds.

In this environment, grades of stainless steel like 304, 316 and even 2205 can suffer Stress Corrosion Cracking (which is hard to detect), especially when these components are under load.

A fatal pool roof collapse in the early 1990s in Europe was due to stress corrosion cracking of 304 roof supports. Then after testing, the report suggested that 6% Mo alloys would NOT crack and subsequently the EU standard EN 13451 was created, which calls for stainless steel grades such as 1.4529 being used above indoor swimming pools for load bearing, safety critical components which are not regularly cleaned and exposed to indoor swimming pool environment.

Areas of application for 1.4529

Material 1.4529, also known as Alloy 926, is an austenitic special steel with a higher corrosion resistance than conventional chrome-nickel steel. Alloy 926 represents an enhancement to Alloy 904L (1.4539) stainless steel, with a raised molybdenum content and additional nitrogen. For this reason, the material is classified in the highest corrosion resistance class, CRC V.

Lindapter Girder Clamps: Safe and Secure Connections

Lindapter Hollo-Bolt™: Safe and Secure Connections

BUMAX® DX 129: The World's Strongest Stainless Steel Bolts

To receive useful info and product updates add your details below